床面にビニルエステルFRP塗料ではなく、ノボラック耐薬品性エポキシ塗料を選択する必要があるのはなぜですか?

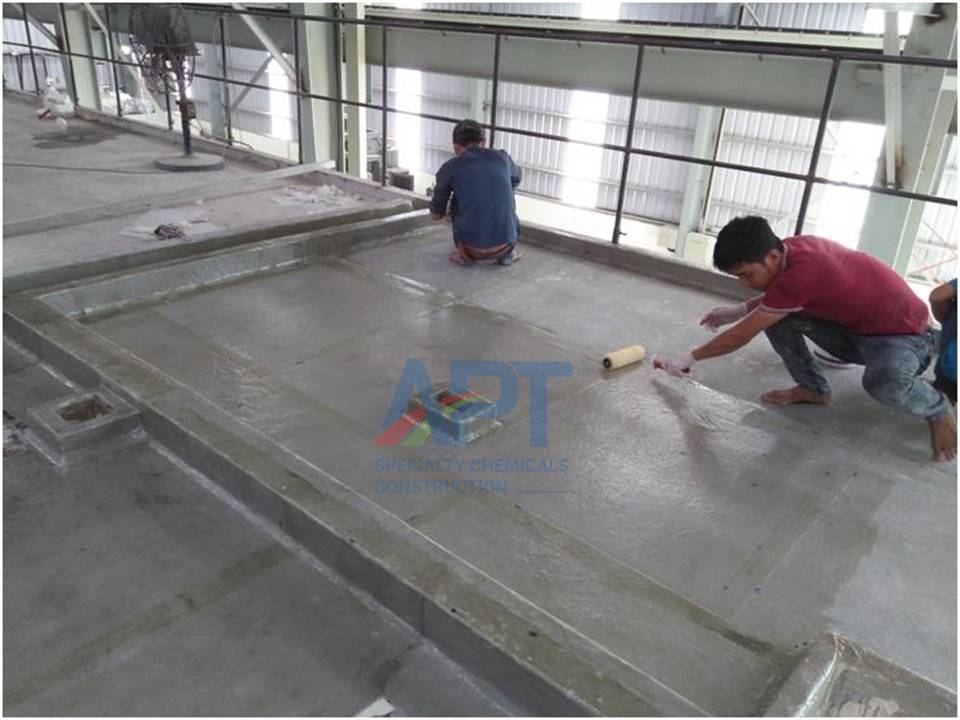

On the market today, there are many types of chemical resistant epoxy paints. But to use for floor surfaces, chemical factories often consider FRP vinyl ester paint and novolac chemical resistant epoxy paint. So what are the differences between these 2 types of products? What chemical resistant paint is best for chemical factory concrete floors? Let find out with APT in the article below!

What is vinyl ester FRP paint?

Vinyl ester FRP is a vinyl ester epoxy coating system with corrosion resistance to a wide variety of acids and alkalis.

What is novolac chemical resistant epoxy paint?

Novolac chemical resistant epoxy paint is a novolac epoxy coating system, has very good chemical resistance when used in horizontal construction.

The differences between novolac chemical resistant epoxy paint and vinyl ester FRP paint on floor surface

|

Features |

Novolac chemical resistant epoxy paint |

Vinyl ester FRP paint |

|

Wear and abrasion resistance |

Novolac chemical resistant epoxy paint has very good wear and abrasion resistance. Trucks and production materials can move comfortably on the floor surface. |

The paint is brittle and fragile, poor wear resistance. |

|

Chemical resistance |

The types of chemicals that are dropped on the floor are usually not too high temperatures. So novolac chemical resistant paint is a reasonable floor paint product to protect the concrete floor. |

Vinyl ester FRP paint is resistant to chemicals with very high temperatures. Suitable for protection of iron and steel surfaces in chemical storage tanks at higher temperatures than used on floor surfaces. |

|

Ability to clean and hygienic |

Novolac epoxy paint creates a smooth, easy-to-clean coating that minimizes the direct impact of grease, dirt and chemicals on the concrete surface. |

Vinyl ester FRP paint also can clean dirt, grease and chemicals that fall on the floor well. |

|

Aesthetics |

Novolac epoxy paint has variety of colors. The delicate colors bring the chemical factory a clean and professional space. |

The coating on the concrete surface of the vinyl chemical resistant paint is colorless, which lacks aesthetics. |

|

Adhesion |

Novolac epoxy paint has adhesion up to 5 Mpa. |

Vinyl ester FRP has adhesion from 3 – 3.5 Mpa. |

|

Construction conditions |

Novolac epoxy paint has low VOC (Volatile Organic Compounds) content, so it has less odor and is friendly with the environment. Create favorable conditions for constructor. |

Vinyl ester FRP paint has a higher VOC (Volatile Organic Compounds) content so it has a heavy odor, it is easy to caught fire, difficult to apply. |

|

Construction and maintenance costs |

Cost of construction and equipment is lower. The paint layer is durable and beautiful, minimizing maintenance costs. |

Construction cost is higher. The wear resistance is poor so causing fragile, and costs a lot of maintenance. |

Which novolac chemical resistant epoxy coating should be selected for factory concrete floor?

KERAGUARD VL100 is novolac two-component, 100% solids coating system that is good chemical resistance when use in cross-surface. KERAGUARD VL100 has good flow ability and high efficiency against both steel and concrete.

This is a chemical resistant paint product that is researched and produced on a modern line of APT Vietnam with many outstanding features, suitable for the concrete floor surface such as:

- Good wear and abrasion resistance with abrasion 0.53 mg / cm, impact resistance 72 kg.cm

- Good chemical resistance.

- Adhesion capacity up to 5 Mpa.

- The content of VOC is low 280 mg / g, low odor, easy to apply.

- Delicate colors, easy to choose.

For more advice on the novolac chemical resistant epoxy paint KERAGUARD VL100 from APT Vietnam, the investors, the factories immediately contact the phone number 0904339299!