帯電防止エポキシ床KERACOTE ESP300はどのようにして静電気を地面に運びますか?

ESD floor can be created by using carpet, rubber, tile, etc. But in fact, epoxy coating is still considered as the most optimal anti-static solution, is chosen by many factories. Understanding this, APT has researched & developed KERACOTE ESP300 – An ESD floor system with good anti-static in 2 resistance ranges are 10^4 – 10^6Ω and 10^6 – 10^9Ω. So, how does anti-static epoxy floor KERACOTE ESP300 bring static electricity to the ground? Let’s find out with APT the operation mechanism as well as the role of each product present in KERACOTE ESP300 system!

Operation mechanism of KERACOTE ESP300

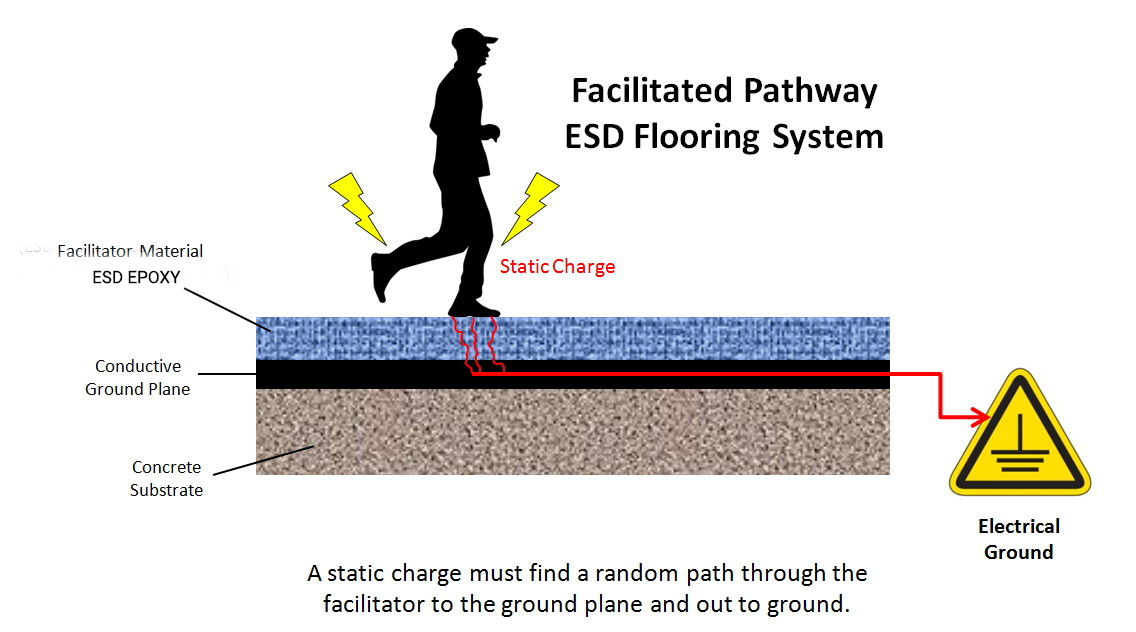

In order to make KERACOTE ESP300 brings static electricity to the ground; anti-static epoxy floor system needs 5 coatings:

- Primer KERASEAL PS60.

- Insulation primer KERASEAL PS20.

- Copper tape and ground connection.

- Conductive primer KERASEAL PSD (black layer).

- Anti-static coating KERACOTE ESP300 (2 layers).

Operation mechanism:

When person, trolley and or chair are moving, static electricity is created and contacted with anti-static epoxy coating on the top of KERACOTE ESP300. Here, static electricity must contact a conductive point and be moved across this surface to underlying ground plane (conductive primer PSD), after that, they are brought to the ground, releasing the charge.

The role of copper tape and grounding point in anti-static floor system KERACOTE ESP300

KERASEAL PSD is completely conduction coating and extend over the surface of floor areas. This layer contacts in many points, with a known or confirmed grounding wire. These grounding contacts are combination between copper tape and grounding paddle. When a charge is brought into this conductive plane, copper tape and the grounding point are the connection between insulating primer (KERASEAL PS20) and conductive primer (KERASEAL PSD), supporting conductive primer move the charge to the ground safely.

Why should use anti-static epoxy floor KERACOTE ESP300?

Good anti-static system: With system has 5 steps, KERACOTE ESP300 ensures maximum anti-static ability in both resistance ranges are 10^4 – 10^6Ω and 10^6 – 10^9Ω. This not every anti-static epoxy paint products can have.

Paint can be used to meet EOS/ESD standard, as well as spark control requirements of explosive and flammable materials. KERACOTE ESP300 can control reactance on the surface, within the range of charge destruction and conductivity, is suitable with the value determined in the EOS/ESD test method of the ESD STM S7.1-2005.

Besides, KERACOTE ESP300 has other advantages such as:

- Solvent-free component helps resin particles to associate tightly, hard surface and high aesthetics.

- Impact strength reaches 80 kg.cm, good wear and abrasion resistance, enhancing floor surface life.

- In the case floor with long-term use, reduce anti-static ability, factories should grind and repaint the floor from KERASEAL PSD, saving 50% for repair cost.

Reputable address to order anti-static epoxy floor KERACOTE ESP300

APT is the direct research and production unit of KERACOTE ESP300. When buy product from APT, you will get:

- Consult suitable products with required resistance range.

- Receive color order according to customer requirements (fast sample time, 3 – 5 days).

- Provide goods with standard product system according to instruction of manufacturer.

- Fast delivery from 3 – 7 days. Can purchase directly from factory.

- Associate with reputable construction unit, has experience in the construction of APT’s anti-static epoxy paint before.

- Follow construction progress, provide technical assistance for projects.

- Have a warrant for product quality from 12 – 24 months.

With the goal “Quality makes brand”, APT believes that we can bring satisfaction in each project. Contact us at Tel 0904 339 299 for free consultation and sample making!