5 factors need to know before choosing anti-static paint for factory

To avoid negative effects from magnetic field in workspace, electronic component manufacturers choose many solutions to prevent charge. In which, anti-static epoxy floor is considered as one of the best solutions that almost component manufacturers use. But in fact, after a short time of use, some factories realize that quality of floor is poor and they do not achieve strict requirements of the working environment. In this article, APT would like to share 5 factors need to know before choosing anti-static paint for factory to help you find out suitable products with high quality.

1. Product’s anti-static ability

Each product has different anti-static abilities. So, it is difficult to choose the suitable product if investors and factories do not know how anti-static products that they need. Normally, with anti-static paint manufacturers, they often bring products with surface resistance.

In addition, factories should follow and listen to employee’s requirement about static electricity issues. From these, there are many overcome solutions in specific areas.

Before construction, construction unit must commit about the floor quality with factories. The resistance level in resistance range according to the feature announced by manufacturer, as well as meets the requirement of factories. Use resistance meter to check and take over after construction.

2. Coating system according to manufacturer’s design

Although anti-static epoxy paint is diversified on the market but not all products are designed with the same coating system.

In some cases, due to lack of knowledge about product or savings and cut down costs, construction contractors reduce construction steps or using substitute products. This thing makes floor cannot reach the required resistance range during floor acceptance. In other case, floor still reach the required resistance range when check and take over, but after a short time of use, floor is quickly degraded and reduced anti-static ability.

Therefore, factories should find out exactly the coating separation system of product which stipulated by manufacturers in order to use the product with standard system, saving time and repairing cost.

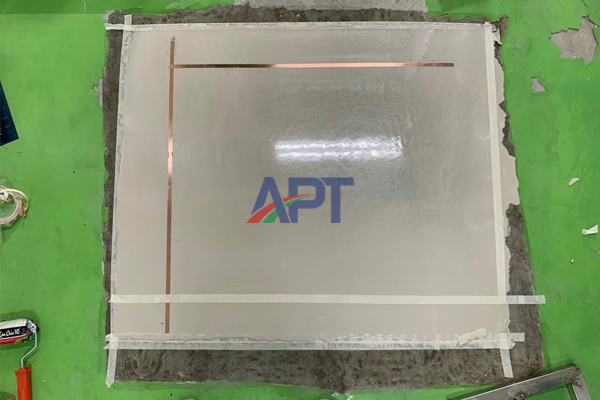

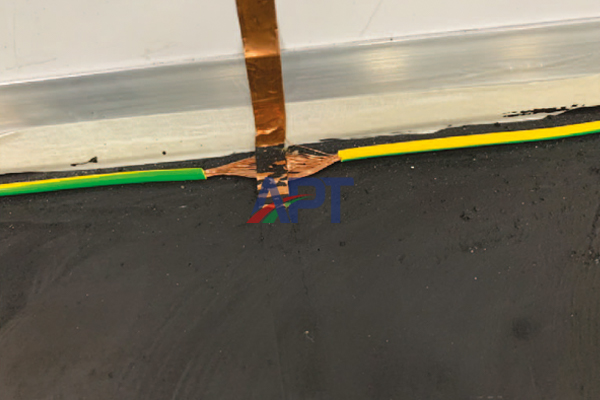

3. Copper tape and electrical grounding

Anti-static floor system requires strict resistance range cannot be completed without copper tape and electrical grounding. Copper tape is connecting step between the conductive primer and insulating primer, helps epoxy floor to bring magnetic field from environment to floor surface and release the charge, ensure occupational safety for working environment. The contact point must be connected to electrical grounding system of factory or directly grounded by independent grounding system. Since then, improving the antistatic ability of final antistatic coating helps the factory:

- Reduce magnetic field created by movement of people and strollers.

- Ensure occupational safety; avoid fire and explosion in production areas.

- Minimize the negative effects of magnetic field on electronic components manufactured in factory.

- Protect all kinds of machinery and equipment in factory. Maximum savings on repair costs.

- Maintain efficient production operations.

4. Aesthetics of surface after application

Depend on concrete quality; the factory floor will have some changes in consumption. But basically, they still have to meet the general standard of manufacturers.

In some cases, due to inexperienced construction unit, the construction floor lacks the standard, the layering is slow, causing the floor to peel, blister or be lumpy after application.

In addition, the paint quality is not ensured; the primers are not applied enough, which also cause the floor loses their glossy and lack of aesthetics.

Therefore, factory should check the sample product before application. Then compare when floor is finished.

5. Prestigious brand

Like many other brands, a prestigious product always brings peace of mind for users. Paint brands with unknown origin will not be appreciated, especially for antistatic epoxy paint – A highly specific product.

KERACOTE ESP300 – The best antistatic floor design on the market today

As a perfect answer to the concern of electronics manufacturing and assembly, KERACOTE ESP300 brings the optimal solution with outstanding antistatic ability. Good antistatic ability at 10^4 – 10^6Ω, good electrostatic dispersion at 10^6 – 10^9Ω.

Product is researched and developed by APT – prestigious brand with diverse industrial floor system, present in 64 provinces and many countries in Southeast Asia such as Laos, Myanmar, Thailand…

System with 5 coatings (5 steps) includes:

-

Primer increases penetration and adhesion.

- Insulating primer

- Copper tape and electrical grounding

- Conductive primer

- Antistatic coating (Finishing coating)

The differences in the component of anti-static paint KERACOTE ESP300

The KERACOTE ESP300 finish coating is created by very small electrical charge fibers. Although, during the initial appear, many investors worried that the fiber will would float on the surface, losing the aesthetics. But in fact, KERACOTE ESP300 asserted the difference based on this component. Tiny electrical charge fiber in the paint can helping them work better throughout the system. The satisfaction of investor in each project is the best evidence for quality and aesthetics of product.

Besides, good wear and abrasion resistance is also a plus point, not only help factory to save repair cost, increase the life of floor surface but also ensure the maintenance of anti-static ability of paint system for a long time use.

Why should buy anti-static paint KERACOTE ESP300 from manufacturer APT?

We are the direct manufacturer of anti-static epoxy paint KERACOTE ESP300. Therefore, during the ordering process, you will get:

- Purchase product with competitive price.

- New product, continuous production

- Support to examine the floor conditions, consult the reasonable consumption standard

- Introduce prestigious construction unit, experienced construction workers

- Free sample for factory before application

Some pictures during examine and making sample for factory of APT

To advice and free sample, factory contact immediately to manufacturer APT at Tel 0904 339 299!